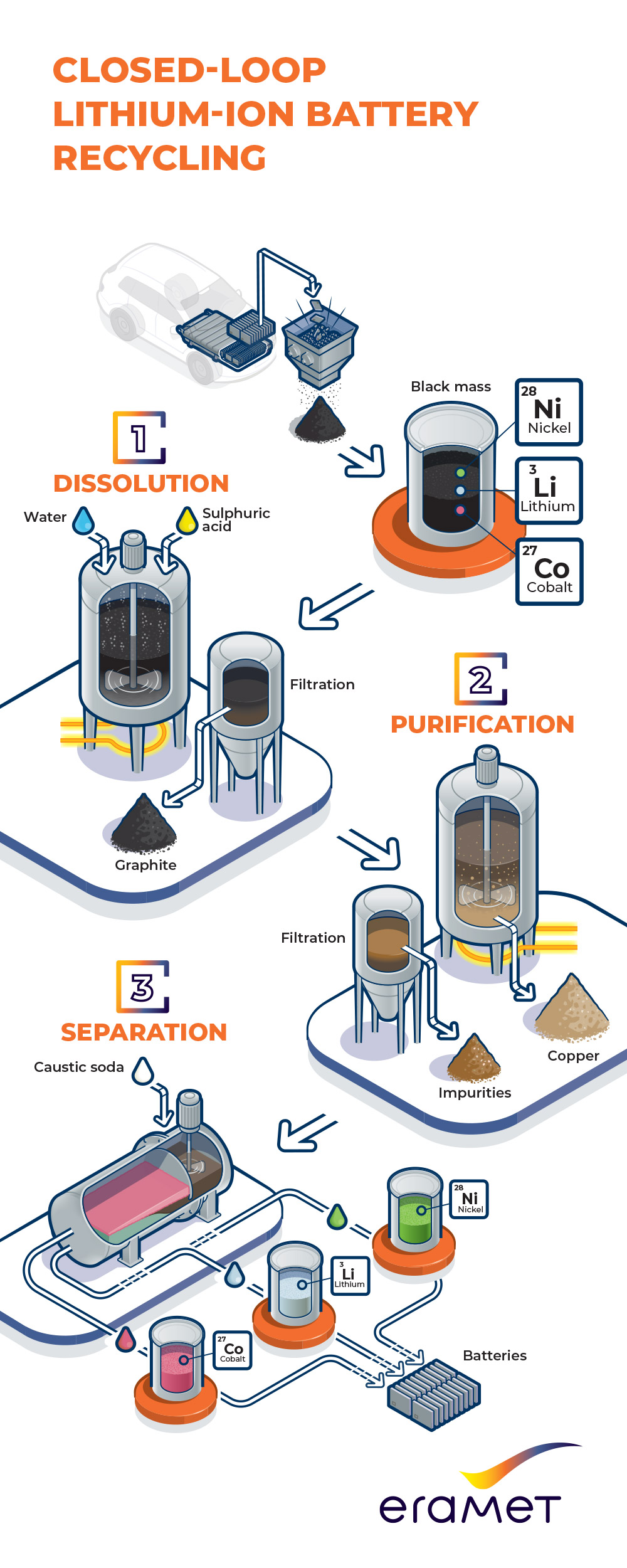

Recycling batteries, a solution for the future

Electric vehicle batteries contain precious metals such as nickel, cobalt and lithium – and these are infinitely recyclable.

As an industrial player committed to promoting a sustainable value chain, Eramet is developing innovative solutions for recycling lithium-ion batteries, with a view to supporting the circular economy and helping to secure metal supplies for Europe’s energy transition.