Exploration

Eramet’s exploration department is responsible for sustaining and developing the Group’s mineral resources through prospection, discovery, and the study of new deposits. This department comprises about twenty employees spanning France (Eramet’s headquarters) and the Group’s key countries, including Indonesia, with teams respectively partially dedicated to nickel exploration.

PT Weda Bay Nickel

In May 2006, Eramet finalized the acquisition of Weda Bay Minerals Inc., a company listed on the Toronto Stock Exchange and the owner of the world-class Weda Bay nickel deposit, located in Halmahera, the main island of North Maluku province. The project’s pre-feasibility studies, conducted by Eramet, began as early as July 2006.

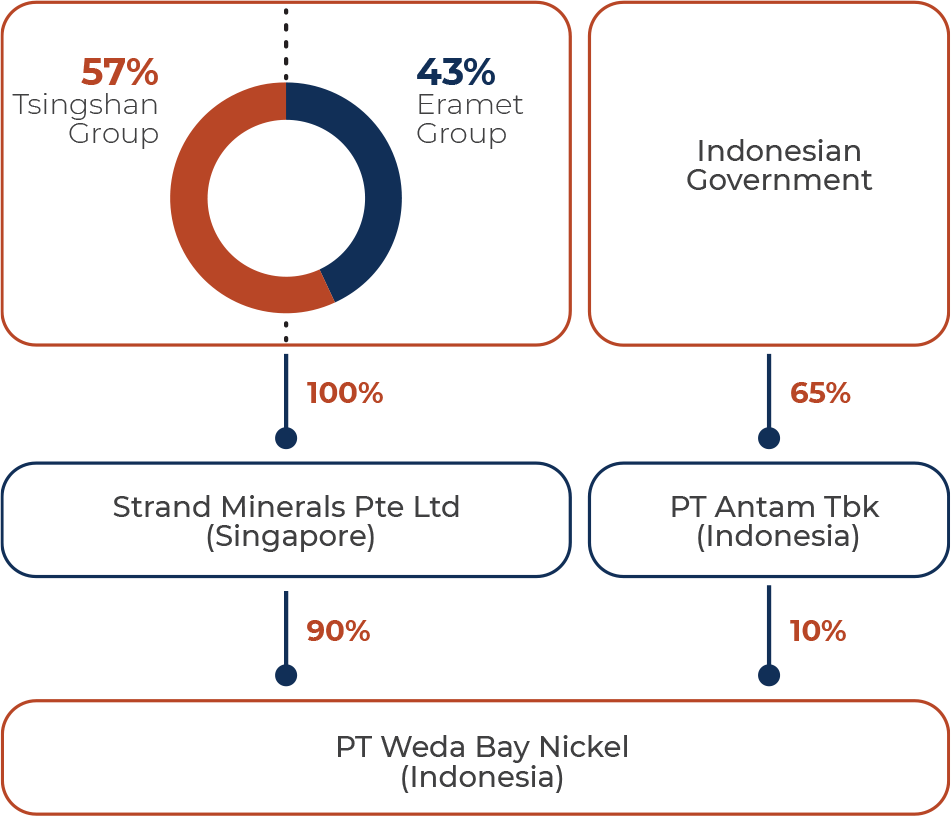

In February 2017, to develop this major mining asset, Eramet’s Board of Directors approved the terms of a framework agreement with the Chinese steel group Tsingshan, the world’s largest stainless-steel producer. Since the finalization of this partnership with Tsingshan, PT Weda Bay Nickel has been owned 90% by Strand Minerals and 10% by the Indonesian state-owned company PT Antam Tbk. Eramet holds 43% of Strand Minerals’ shares, while the Tsingshan group, through its subsidiary Newstride Ltd Co, holds 57%. As a minority shareholder, Eramet therefore indirectly holds 38.7% of PT Weda Bay Nickel.

PT Weda Bay Nickel’s activities encompass both the nickel ore extraction (the mine) and its processing at an industrial facility, located within the industrial park operated by PT Indonesia Weda Bay Industrial Park (IWIP), a company owned by the Tsingshan group.

The Mine

The mining concession operated by PT Weda Bay Nickel, called CoW (Contract of Work), covers an area of 47,000 hectares, including 15 identified and evaluated deposits. Their exploitation began at the end of 2019 and is conducted in open-pit mining. The concession (Contract of Work) for the deposit was obtained for a period of 30 years.

During mining, PT Weda Bay Nickel extracts materials which are separated according to their future use. Firstly, the topsoil is stored separately in the immediate vicinity of the pits in order to be reused to rehabilitate and revegetate the mine after exploitation. Then the tailings which have no industrial use are stored in waste dumps, which are rehabilitated once completed. As for the nickel ores, they are separated according to their grade:

- High- and medium-grade saprolitic nickel ores (> 1.5% and > 1.2% nickel content) are sent to PT Weda Bay Nickel’s pyrometallurgical plant (RKEF).

- From 2023, nickel-bearing laterites (between 1% and 1.3% nickel content) are also processed in High-Pressure Acid Leaching (HPAL) plants at the PT Indonesia Weda Bay Industrial Park (IWIP).

These plants produce either nickel ferroalloys (NPI) for the stainless steel market, or battery-grade nickel in the form of an intermediate product (Mixed Hydroxide Product – MHP).

The Metallurgical Plant

PT Weda Bay Nickel’s plant produces a low-grade nickel ferroalloy (between 12 % and 15 % of nickel content) that is directly marketable. The plant owns four RKEF (Rotary Kiln Electrical Furnace) type production lines. First, the ore is dried by the heat recovered from downstream furnaces. It is then calcinated and then melted in four EAF (Electrical Arc Furnace) furnaces. The plant’s annual production capacity ranges between 30 kt and 35 kt of nickel contained in the form of nickel ferroalloy (depending on the nickel content of the ore consumed). The plant is located at the foot of the mining concession, in the IWIP. The industrial park, located on the coast, hosts numerous manufacturing activities, including other nickel processing metallurgical plants.

Indonésie : our news

1 September 2025