Eramet is the world’s second-largest producer of manganese alloys. Its production capacity is spread over three continents, via its subsidiaries in the United States (Eramet Marietta), Norway (Eramet Norway), France (Comilog Dunkerque), and the Complexe métallurgique de Moanda (C2M) in Gabon. These six plants are located close to dynamic steelmaking zones near major markets, guaranteeing optimum supply to European and American steelmakers.

Eramet is committed to respecting the specifications of its manganese alloys across its entire product range. A commitment that has proved its worth, given the Group’s long-standing relationships with its customers.

Our manganese alloys

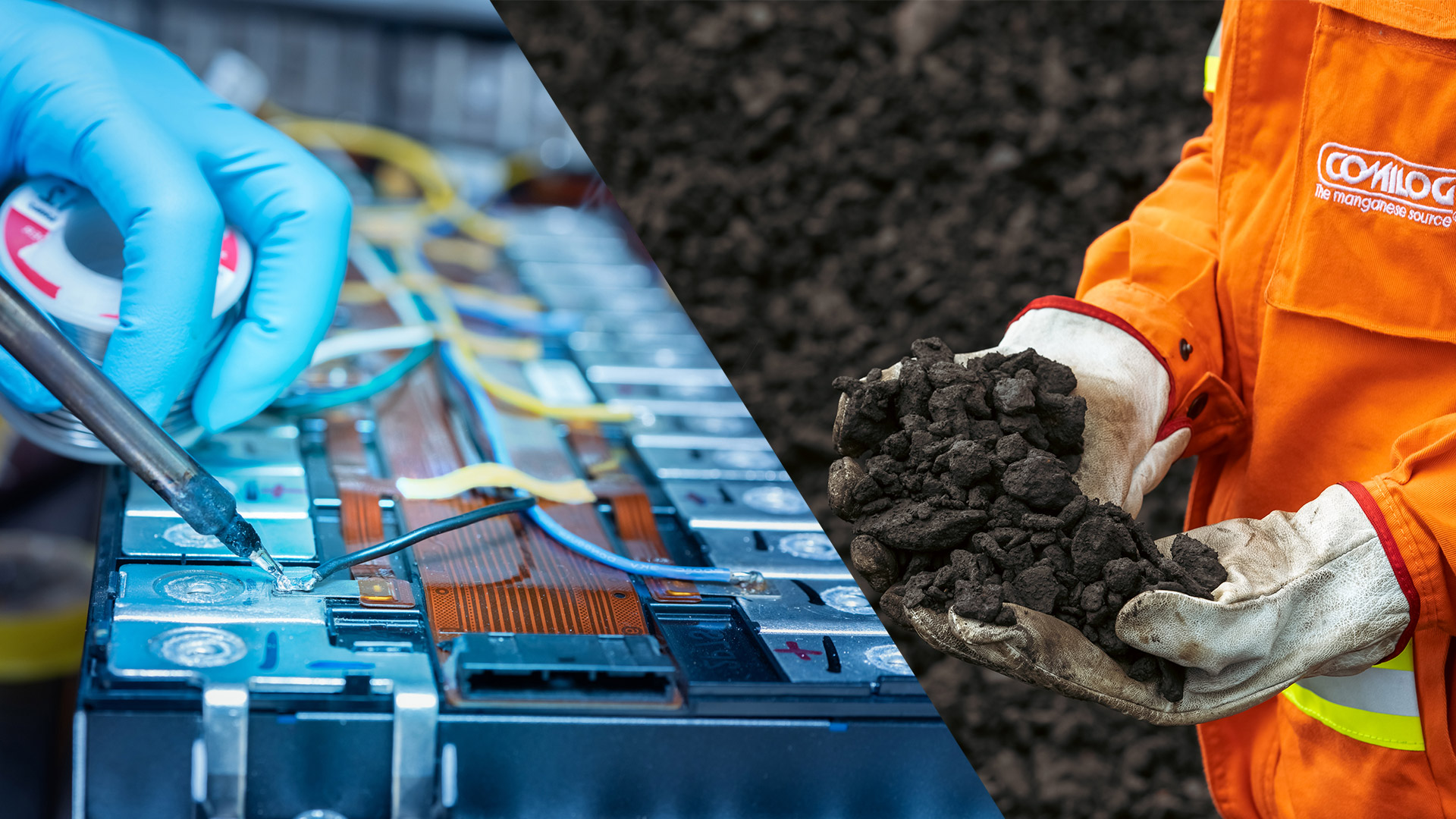

Manganese alloys are produced by smelting manganese ore at a temperature of around 1,600°C. This operation, known as metallurgical reduction, is carried out by adding metallurgical coke in furnaces, the vast majority of which are electric furnaces.

The sources of electricity used by Eramet’s plants in Gabon, Norway (hydroelectricity) and France (nuclear essentially) enable the company to produce alloys with a particularly low carbon footprint.

The range of alloys produced by Eramet is very broad and includes standard products (high-carbon ferromanganese, silicomanganese), as well as so-called refined products (medium- and low-carbon ferromanganese, low-carbon silicomanganese).

Despite the small share of refined alloys in global alloy production, they represent the highest value-added products, due to their low carbon and high manganese content and their exposure to the energy and automotive markets.