Eramet’s environmental policy is designed to promote a more circular economy that uses primary resources more sparingly, based on three key areas of action:

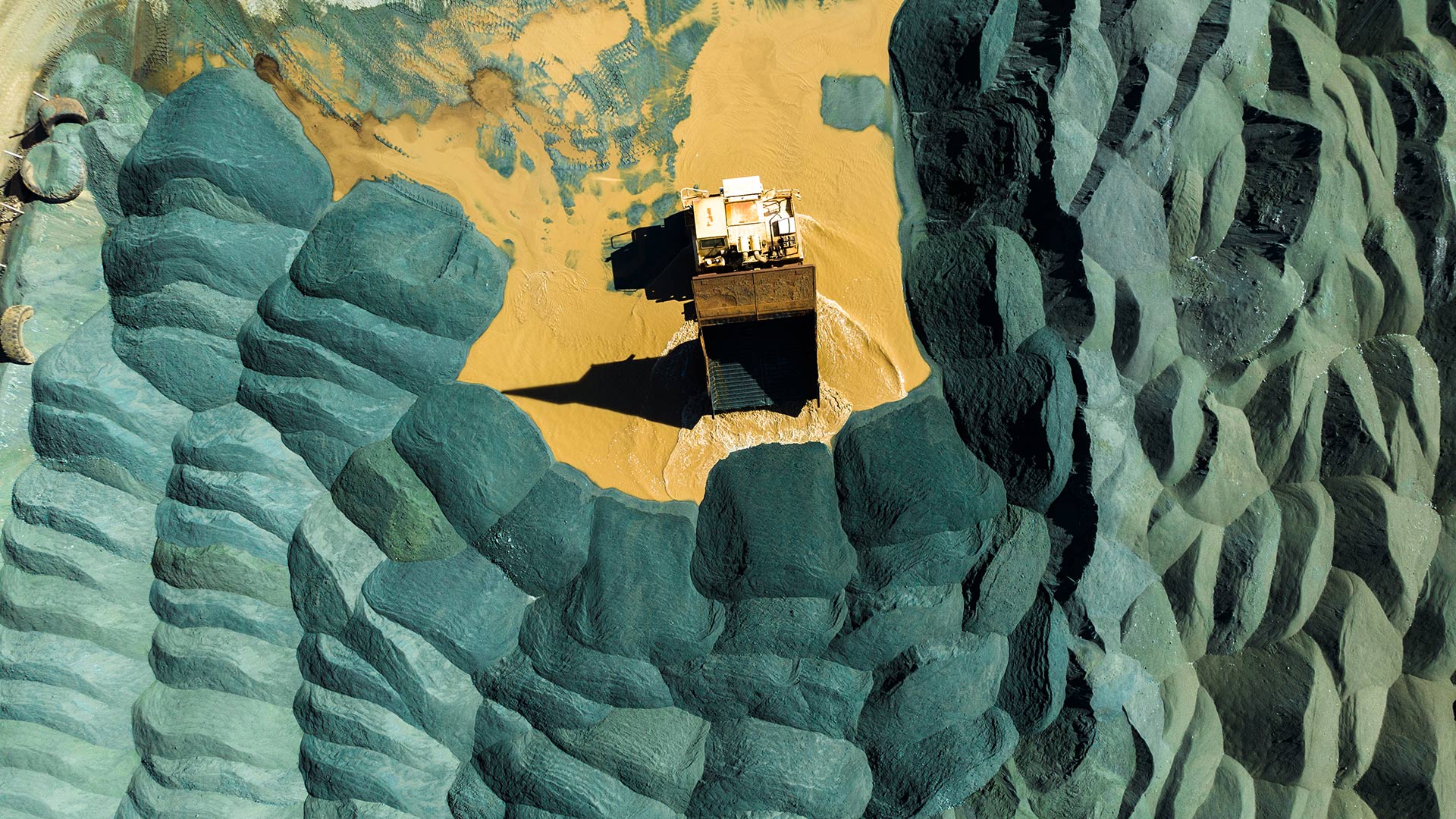

- Optimal management of mining resources: The mining industry has a crucial role to play in increasing the efficiency of natural resource use. Firstly, by processing lower-grade ore, which reduces the amount of waste rock. Secondly, by recovering as much material as possible from the mine tailings resulting from ore concentration processes. This makes it possible to extract more resources with virtually no increase in environmental impact.

- Maximizing the use of recycled materials: Eramet strives to incorporate as many secondary raw materials as possible into its production processes, to minimize the consumption of primary raw materials, and to recover as much of the waste generated by its activities as possible (internally or externally).

- Participation in industrial and regional ecological initiatives: Wherever possible, Eramet’s industrial sites take part in local industrial ecological initiatives by sharing the heat, energy or fluids produced by their activities, or conversely by using fluids from neighboring plants.

Circular economy: our latest news

28 July 2020